Thailand: Tearing down the automotive industry

Every company has its competitor — and within the automotive industry, competition is fierce. Some 14 major companies control more than 60 car brands around the world, and independent automakers like Tesla, VinFast and China’s “big four” are shaking up the industry.

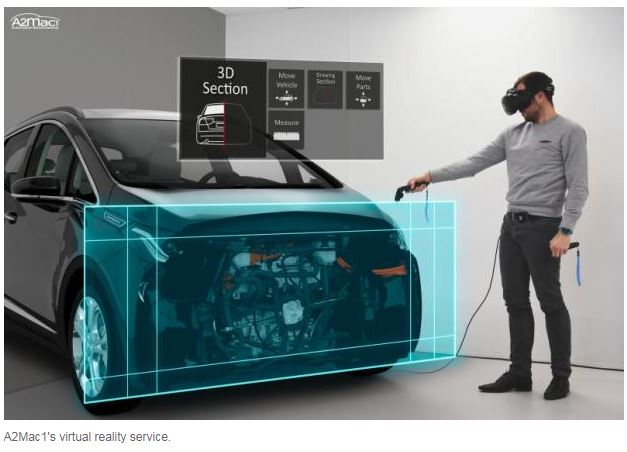

With new cars being developed and manufactured at rapid speed, automakers have to keep up with the technologies, trends and competitive pressures of today’s complex design and manufacturing environments — and A2Mac1 aims to help them do just that.

French company A2Mac1 opened a Thai subsidiary last year. Founded in France in 1997 and with a presence in Europe, the US, China, India, Japan and South Korea, A2Mac1 believes it’s the only company in the world doing what it does.

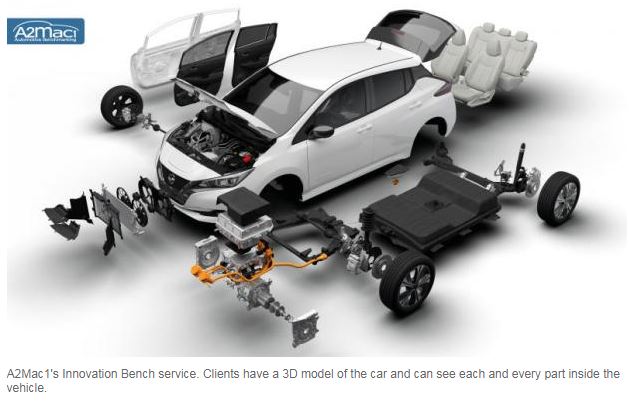

A2Mac1 acquires the latest and newest automobiles in the market. Employees tear down the cars systematically, study each and every detail of each and every part of the vehicle and put the information in a giant database with which competitors’ engineers can compare and advance their own manufacturing methods.

With its one-of-a-kind business model, the company has demonstrated rapid growth, growing by 15% a year in revenue over the last five years. Furthermore, it was recently acquired by Five Arrows Principal Investments (FAPI) and is run by co-chief executives Jacques Leveille Nizerolle and Bertrand Sicot — the former CEOs of CATIA and Solidworks, respectively.

“We tear down 100 cars around the world per year,” said Anthony Ky, the 28-year-old general manager of A2Mac1 Asean, who is based in Thailand. “Before I worked for A2Mac1, I wouldn’t think that car makers study their competitors to this extent in detail. But when you work with them, they really study every single part and every technology that their competitor uses.

A2Mac1, for example, has a service called Body in White. It refers to the frame of the car, composed of metal sheets. Technicians dismantle all the metal sheets, cut samples, put them in a spectrometer and determine the percentage of each chemical composition that makes up the metal.

“What percentage carbon, aluminium and so on,” Mr Ky said.

“What percentage carbon, aluminium and so on,” Mr Ky said.

Established as a family business in the rural town of Hary, France by the Mouliere brothers, the business concept came during the time when digital cameras started entering the market.

“They had an idea of taking pictures of every car from the same angle, from the same distance, so future customers could compare pictures,” Mr Ky said. “They took their camera and went to a motor show and they took pictures of the cars, but always from the same angle. That’s where the business started. With more and more discussions, customers bought our services and said ‘you guys know how to take pictures, maybe you should further push your studies’.”

Following customer requests, A2Mac1 started acquiring cars, tearing them down and taking pictures of each and every part. Year after year, the company introduced new and more advanced studies based on their customers’ requests. A2Mac1 works with most global automotive original equipment manufacturers (OEMs) and more than 200 automotive suppliers, thanks to the company’s extremely detailed and organised data analysis.

“I’m quite sure some OEMs are [tearing down vehicles] right now,” Mr Ky said. “They buy their competitor’s car for engineers to study. But the reason why they work with us is because we have the knowledge for teardowns. we follow a standardised process, and we know how to organise data so nothing is lost.”

Six technicians need one month to tear down a car. There would be at least 1,200 parts torn down and handled, more than 30,000 standardised photos taken, and every property of each part, including the weight, material, supplier and coating, is documented, organised and easily compared.

“The other reason why we’re unique is because of our business model,” Mr Ky said. “What I do is I go see each customer and ask them to give me two vehicles. Let’s say I have four customers. If you’re my customer, you give me two vehicles, but you get back eight vehicles. It’s cost-saving for you. But of course what’s important for A2Mac1 is keeping confidentiality.”

With constant technological advances developing within the automotive industry, A2Mac1’s goal is to follow the technology within the industry.

“We know EV hybrid technology is coming, so we develop services that can help our customer benchmark this technology,” Mr Ky said. “We know that autonomous cars are also coming, so we have a series of services that we use to try cover this scope.

“Starting last year we developed a new service called Innovation Bench. What we do is instead of taking pictures of the parts we tear down, we fully 3D-scan the whole car. Our customers can navigate and benchmark the car in a 3D environment. We are the first and only one in the world doing this.”

What’s even more intriguing is that the company has just 500 staff members, yet it’s growing quietly at a rapid pace. At only 21 years old, it seems as if A2Mac1 will continue to be a quiet force within the automotive industry for a long time to come.

Source: https://www.bangkokpost.com/business/news/1668896/tearing-down-the-automotive-industry

Thailand

Thailand