Industrial robots: mechanisms enabling Thai industries to compete on the world stage

The Thai-German Institute (TGI) recognises that for Thai industry to realise its potential depends on high technology, especially the use of automation and robotic systems for research and development, and transfers of technological know-how to Thai workers in production industries across the board.

Mr. Varin Rodphothong, Vice President of Manufacturing Automation and Robot Center, The Thai-German Institute, explained the use of industrial robots in the Thai Industry 4.0 era.

“In the past, industrial robots were only utilised in large industrial enterprises owned by foreign companies that moved their production bases to Thailand, such as the automotive industry. These companies brought their technology to Thailand and employed Thai workers. Training and skills development were therefore needed to enable the Thai workforce to cope with the new technology.”

“TGI appreciates that automation and robotics systems are needed for Thai Industry 4.0. Looking at robot-human ratios, we found that 400-500 robots had replaced 10,000 workers in Korea, while 50-60 robots had replaced 10,000 workers in Thailand. This ranked Thailand 9th-10th in global for the use of robots. The average robot-human ratio is 66 to 10,000.

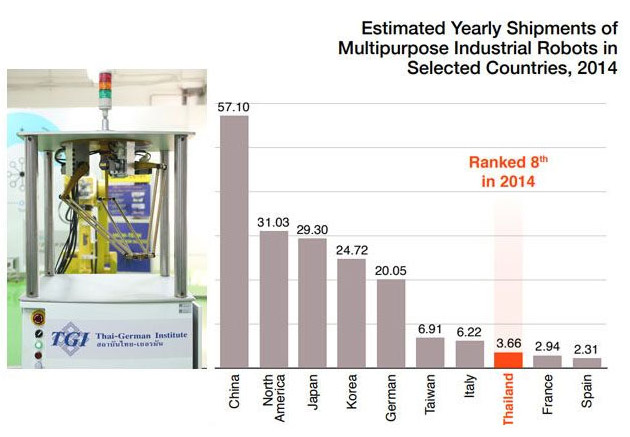

“In 2014, Thailand ranked 8th globally for importing robots to make up the deficiency in human workers. Industries deploying robots were also looking to increase their production efficiency and capability to compete on the world stage.”

Mr. Varin continued: “Thailand has a tendency to use industrial robots extensively. Some 300,000-400,000 million baht was spent on importing robots alone. Since the government announced 10 targeted industries to boost the Thai economy, the use of industrial robots has become a major factor. Moreover, a cabinet resolution on 29 August 2017 approved the development of automatic and robotic systems, and assigned the Ministry of Industry to lead the follow up of all involved operations to ensure tangible results.”

Five measures will be implemented to promote automation and robotics implementation:

1. Marketing: Motivate demand for automation and robotics in manufacturing industries. Target groups include entrepreneurs looking to replace old systems with automation and robotics. These entrepreneurs need to allocate 80%-90% of their total investment for this purpose.

2. System Integrator (SI): Increase efficiency with system integrators to gear up for future expansion of automation and robotic use. So far only 200 potential system integrators are available.

3. Supply: Generate supply to promote standard production and international-standard automation and robotic products.

4. Center of Robotics Excellence (CoRE): Develop robotics technology for various applications as mechanisms to expedite development of automation and robotic industries. This will be done by integrating eight lead organisations. TGI will cooperate with private overseas organisations to develop at least 150 products within five years.

5. Other measures

“National Science Technology and Innovation Policy Office (STI), Ministry of Science and Technology, has implemented a prototype robotics development project, comprising seven types of stationary and mobile robots, including: Cartesian, SCARA, Articulated, Delta, Mobile, Cylindrical and Spherical types.”

“STI is providing a budget to TGI and the Federation of Thai Industries to build the platform. Once TRL5 (Technology Readiness Level 5) is completed, Thai industrial entrepreneurs will be able to use these technologies for their commercial purposes. Moreover, ISs can design products for the 10 targeted industries,” concluded Mr. Varin.

Source: https://www.bangkokpost.com/business/news/1366283/industrial-robots-mechanisms-enabling-thai-industries-to-compete-on-the-world-stage

English

English